The purpose of duct systems is to move air across a structure. Ducts that are not well-designed create discomfort and increased energy bills. It also causes air pollution and extreme noise levels. But a well-designed ducting system can keep your home warm no matter what the weather is like outside. It also decreases your heating and cooling costs. HVAC Cleaning in Duluth, GA, is a vital resource for building a high-performing duct system. Following the rules for HVAC ductwork design results in a good quality product.

Before we begin, let’s look at how to detect if you need a new HVAC ductwork design:

Old ducts harm the performance, efficiency, and air quality of your system. When examining your aged HVAC ductwork design, consider the following factors.

- When did you install the ducts? The original equipment’s seals, joints, and seams can fail in less than ten years.

- After identifying the ducts’ age, inspect them in visible parts such as the attic or crawl space. Check the ductwork for failing duct tape and any damaged spans. Keep an eye out for extra dust coming from the seams, which can signal air leaks, and note any corrosion or rust.

- What is the condition of the airflow in your rooms? Rooms with poor airflow may have duct segments that have become broken or blocked with dust. As a result, there may be air leaks in the ductwork and thermal loss due to degrading insulation.

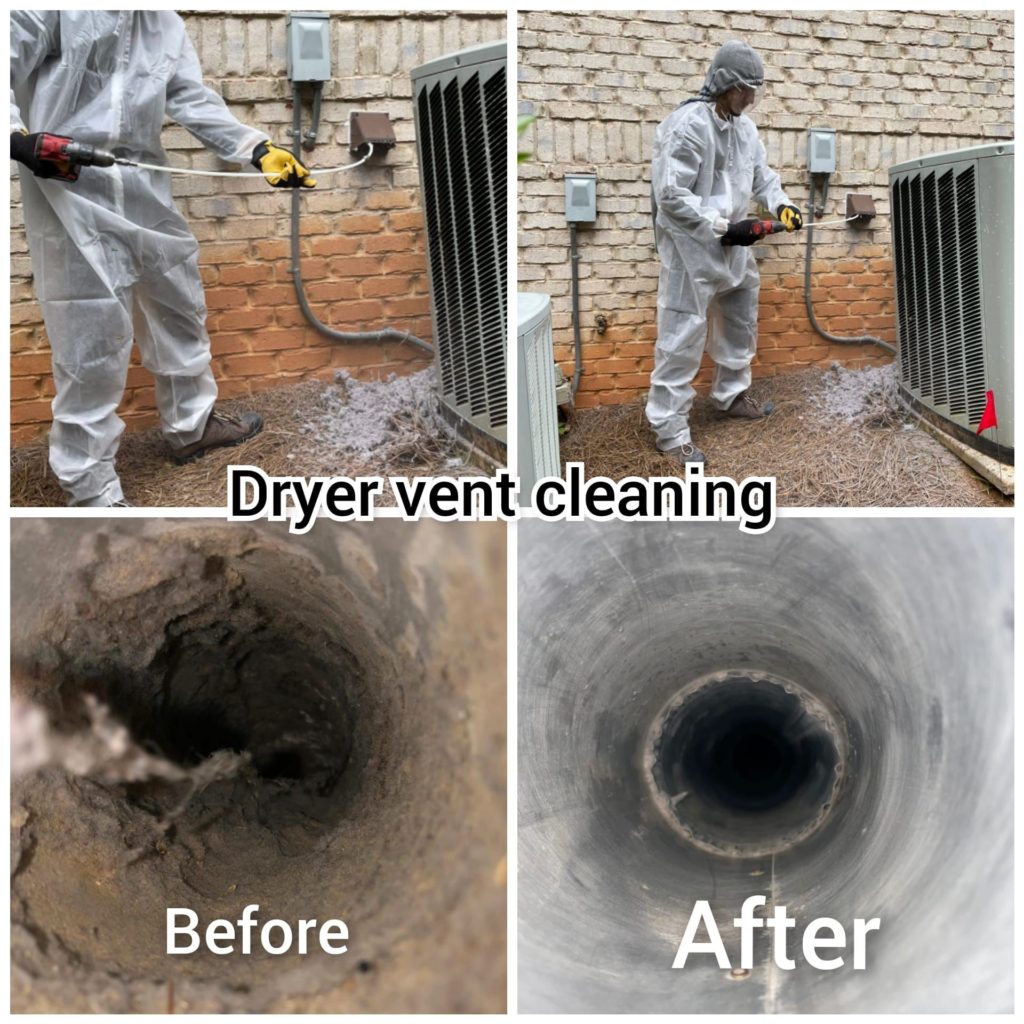

After gathering the information, contact Dryer Vent Cleaning in Duluth, GA. Next, it is to arrange a duct blower test. First, they try to force ducts with a blower fan. They also use a computer to estimate the quantity of air leakage about total airflow.

Effects of the bad HVAC Ductwork Design

The average HVAC duct system is approximately 60% efficient. Unfortunately, it means air isn’t flowing through your room and HVAC system as it should. As a result, it leads to a variety of negative impacts, including:

- Because of obstructed airflow, your space may have hot and cold spots, breeze, and stuffy air.

- It also includes extra damage to your air conditioner. Again, it must operate longer and be harder to adjust for faults in the ducting design. Thus, it results in more breakdowns and shorter equipment life.

- A lack of proper airflow can lead to increased dust, pollutants, gases. It also leads to mold growth due to excessive humidity.

- Unbalanced air pressure causes the smell to remain, doors to bang on their own. It also causes distracting noise levels in your environment.

Before designing the ductwork

The HVAC ductwork design is essential. But there are a few vital stages that you must complete before.

Calculations and CFM

The first step is to calculate the heating and cooling load using a technique. Next, you must understand how much heating and cooling you want for each room (BTU/hr). Then convert those BTU per hour needs to cubic feet per minute. Next, it is to determine airflow requirements for each room (cfm). The software takes care of it for you. After finding the BTU/hr and cfm values, choose the proper heating and cooling equipment. Next, verify that you consider the home’s internal and exterior design conditions. The heating and cooling load is the term used to describe this.

Impacts of the figure

The figures have an impact on the selection of a system blower with the correct output. It also affects duct sizing and optimal design. Static air pressure inside the ducts is one factor to consider. It acts as a barrier to warm and cooling airflow. Also, the number of fittings and the internal surface increases air friction. As a result, it obstructs the airflow and has an impact on the result. All these elements contribute to the system’s computed “total effective length.”

Steps to Design HVAC Ductwork

Draw a rough sketch

Draw a basic sketch of the desired air distribution system for the home. After that, display the equipment placement, register, and return locations. Also, show the airflow requirements for each room, each supply register. Then display the position and lengths of ductwork to connect it all. More than one sketch may be necessary. It is to establish the optimal duct plan that depends on the architectural layout. It also identifies the structural parts of the home.

Size of the ductwork

Size the ductwork, which takes into account blower performance. Sizing the duct also accounts for the room-by-room cfm. As mentioned earlier, CFM needs both cooling and heating ducting. It also determines the distance to each register or return. The fittings and the type of ducting material, and any other constraints are all taken into account.

Fabrication

It is the step at which the ideas on paper begin to take shape. Create a fabrication list. The installation of well-sealed ducting begins in the shop and continues throughout.

Installation

It is the point at which an HVAC ductwork design can be formed or ruined. Use rounded rectangular reducers for good air movement. Any square or right-angle connectors in a duct system blocks air movement. Pay proper care to the duct system’s junctions. Cover the joint by using duct tape. If joints do not seal, the total system runs at a lower efficiency, wasting energy.

HVAC Ductwork Design Mistakes

Here are some common ductwork design mistakes that limit air conditioning performance:

Size of the duct

Contractors may make the error of:

- forgetting to consider the type of air conditioning system,

- the load requirements of different rooms,

- the location of ducts and equipment

- and the correct materials used to build them.

All these elements affect the sizing of your ducts

Long duct runs

Due to the poor layout, HVAC equipment and duct systems are placed far from the cooling space. As a result, your system may have a hard time moving air to some regions of the space if you have a long duct run.

Sharp ductwork

Sharp ductwork reduces the amount of air that delivers to the space for cooling.

Air leaks

Wrong sealed HVAC ductwork might leak cooled air into the walls. It does no good for the occupants of your area.