A flexible air duct is a long ductwork tube. It is more adaptable to difficult living environments than inflexible ducting. To establish a duct network, many HVAC blend rigid and flex air ducts. Because that is the best use of the available space in the house. Even though a flexible air duct is more accessible, it should never bend at more than a straight angle and support it.

Flex ducts are rarely well installed. Whether you’ve ever seen a kinked or drooping flex duct and thought if it was an issue, you were right! Because the flex duct is flexible, it flexes in ways that we do not want it to. As a result, there is poor airflow and ineffective HVAC systems.

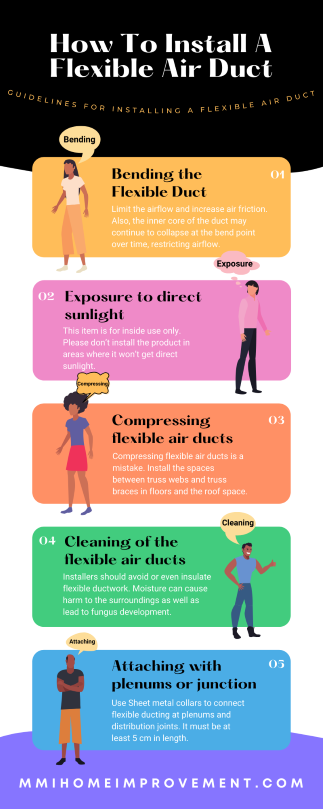

Guidelines for installing a flexible air duct

We should follow the manufacturer’s recommendations while installing flexible ducting. The following criteria apply to the majority of flexible duct systems.

Bending the Flexible Duct

Bending flexible ducting across or around the frame, pipes, and other objects is not recommended. Such bends have the potential to reduce the size of the duct at the endpoint. So, limit the airflow and increase air friction. Also, the inner core of the duct may continue to collapse at the bend point over time, restricting airflow. Bending a flexible air duct is one of the most typical mistakes. According to air duct cleaning, Alpharetta radius at the centerline is less than one duct diameter. These types of bends also reduce airflow and increase air friction. It is yet another typical installation fault.

Exposure to direct sunlight

According to HVAC cleaning Alpharetta, this item is for inside use only. Please don’t install the product in areas where it won’t get direct sunlight. Prolonged exposure to sunlight may cause the vapor barrier to degrade. Also, don’t install near hot equipment that is hotter than the specified flexible air duct temperature.

Use the below code to Embed this infographic

Compressing Flexible Air Ducts

Route the flexible air duct across spaces at least as big as the duct inner core’s diameter. Air duct cleaning Alpharetta suggests that compressing flexible air ducts is a mistake. Instead, squeeze the ducts to fit into tight places. For example, install the spaces between truss webs and truss braces in floors and the roof space. When routed ducts are between different places, this installation problem occurs. For example, between the garage roof space and the conditioned area roof space.

Minor ducts

Furthermore, minor duct compression is acceptable. But don’t crush the inner core. Support the horizontal flexible air duct at 1.5-meter intervals and the vertical at no more than 1.8-meter intervals. The largest sag between supports is 2.5cm for every 30cm of horizontal run. Independent of the flex duct, support plenums, and distribution connectors. The width of the support straps or other support material should be at least 3.8 cm.

Cleaning of the flexible air ducts

According to HVAC Cleaning Alpharetta, cleaning is important. Flexible ducting running through unconditioned areas should have air space on both sides. Installers should avoid or even insulate flexible ductwork. In humid regions, this is more significant than in dry climates. Moisture can collect on flexible ducting that is not ventilated. This moisture can cause harm to the surroundings as well as lead to fungus development. Keep flexible air ducts dry during and after construction. When it becomes wet, the insulation can stay moist for years. As a result, it can create a breeding environment for fungus growth. Duct boots, particularly floor ducts, should also be clean throughout and after construction.

Connecting and joining

- Install all connections, joints, and splices by the manufacturer’s specifications.

- List all tapes, mastics, and non-metallic fasteners used for flexible duct field installation. Moreover, label it by Standard UL 181B — Closure Systems for Use with and Air Connectors. Non-metallic fasteners have a most positive pressure of 6-inch w.g.

- Sheet metal collars for flexible ducts must be at least two inches long and beaded.

- Air duct cleaning Alpharetta suggests sheet metal sleeves should be at least 4 inches long and beaded. As we use it to connect two lengths of flexible duct

Attaching with plenums or junction

Use Sheet metal collars to connect flexible ducting at plenums and distribution joints. It must be at least 5 cm in length. The length of the metal sleeves should be at least 10 cm long. Its purpose is to join two lengths of flexible ductwork. Use at least two wraps of an authorized metal tape to make joints airtight. It is to connect the inner core of the duct at collars and distribution connections. A clamp is also used but it is not necessary. You can splice two lengths of flexible ductwork using tape and clamps.

At plenums and distribution joints, connect flexible ductwork. It is to install fire-blocking whenever flexible ducting penetrates floor and ceiling components. As well as where it penetrates connections between vertical and horizontal areas. Unfaced batt mineral wool or fiberglass insulation may use as a fire-stopping material. Avoid installing flexible ducting that penetrates a fire-rated assembly. Unless authority with jurisdiction allows it. It incorporates flexible air ducts linked to garage boots.

Common installation error

- Trunk supply ducts and central return ducts curve at greater than a 45-degree angle across a barrier or support. Thus, these ducts are not acceptable. Also, those that make a vertical bend over an obstacle may become even more so with time.

- Trunk supply ducts and central return ducts with an inner core more than 20% constrained in size. Because the affected boot causes restrictions. Moreover, it may be appropriate for a duct servicing a single boot.

- Duct bends that deviate from the one-duct-diameter-bend rule.

- HVAC cleaning Alpharetta suggests horizontal ducts that go out of a plenum or into a boot.

- Ducts that have a slack collar or no metal sleeve at a splice are a common error.

- Air duct cleaning Alpharetta suggests ducts with a punctured inner core are errors.

- Ducts that are near to a heat-generating appliance vent are also considered an error.

- Ducts leak a “much” volume of conditioned air at a plenum collar, splice, or junction.

- Avoid ducts that come into contact with the ground, as well as ducts buried in insulation. If there is evidence of condensation on or around the duct.

- Wet insulation in ducts is caused by causes such as rain or plumbing leaks.