When it comes to home tasks, your clothes dryer is essential. It’s easy to take things for granted when they’re working. But, if dryer won’t spin or breaks, you know how helpful it is to have a good dryer in your home.

Moreover, this article discusses the most common causes of a dryer won’t spin and what you can do to fix the problem. Dryer vent cleaning Atlanta helps in repairing the dryer drum that is not rotating. It can restore your appliance to proper operating order!

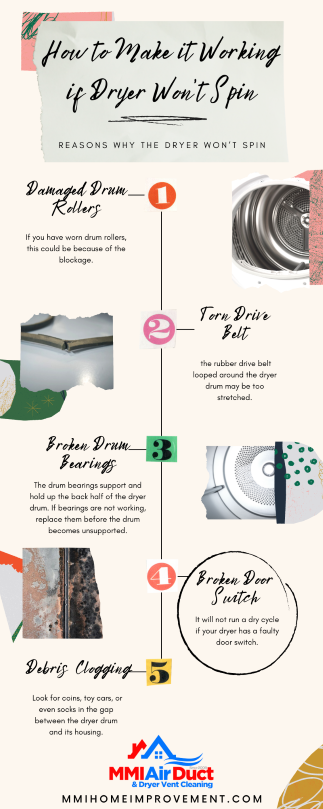

Reasons Why the Dryer Won’t Spin

Many factors can prevent your dryer from doing its job. A common problem is a dryer that does not spin. Some professionals state there could be many reasons why your dryer won’t spin. Here are a few common causes of a dryer that won’t turn.

Damaged Drum Rollers

In worn drum rollers, there is insufficient friction to move the dryer’s drum. If you have worn drum rollers, this could be because of the blockage. Additionally, because of the jam, the dryer’s drum does not spin.

Torn Drive Belt

The rubber driving belt wraps around the dryer tub. It links to the engine and uses friction to turn the drum. But, if the dryer won’t spin, it may be because of two reasons. First, the rubber drive belt looped around the dryer drum may be too stretched. Second, it is not creating enough friction to turn. So, according to MMI, if your dryer isn’t spinning, it could be due to a broken drive belt.

Damaged Roller Axles

The axles of the wheels that allow the dryer drum to rotate are drum roller axles. MMI professionals state that if these axles are not spinning, the dryer won’t spin and become stuck.

Broken Drum Glides

The drum glides are the critical plastic coatings. It travels along the drum rollers when the dryer runs. If the drum glides become worn, the dryer begins to stick to the rollers and stop spinning.

It isn’t Plugged in

The first way is to ensure that your dryer is connected. Next, check for any power-related issues, such as a tripped circuit breaker or a blown fuse.

There is a Broken Door Switch.

It will not run a dry cycle if your dryer has a faulty door switch. You may determine if it is terrible if the drum light does not turn off.

The Thermal Fuse isn’t Working.

It is a safety mechanism attached to the dryer’s heating chamber. According to MMI, If the thermal fuse blows, it affects the main power supply.

The Dryer’s Interior may be Filthy.

Lint and other particles might find their way inside the dryer housing. As the crud builds up, the motor may stop performing. Sometimes all it takes to get a dryer running again is to vacuum the dust out of it. Professionals state that if the vacuum isn’t removing all the particles, try a leaf blower.

Debris is Clogging the Drum.

Someone may forget to empty their pockets before beginning a cycle of washing. Look for coins, toy cars, or even socks in the gap between the dryer drum and its housing. Needle-nose pliers come in use for removing any small stuff you may come across.

Solutions for a Dryer Won’t Spin

Use the below code to Embed this infographic

According to MMI, here are some solutions for a dryer that won’t spin.

Checking the Power Supply to Your Dryer If It Isn’t Spinning

Checking the power supply is a routine procedure of every dryer if the dryer won’t spin. Begin by looking for the plugin for the power outlet. Check the fuse box on the wall next to see if there is a blown fuse. Finally, use a multimeter to test the power outlet. Also, check the various components of the drying and spinning motors.

Repairing the Drive Belt

The drive belt interacts with the engine to spin the drum of the dryer. It is one of the most popular ways to fix a dryer that isn’t turning. Unclip the metal clamps holding the lid down and tilt the cover back to open the top of the dryer. HVAC Cleaning Atlanta suggests the belt should wrap around the drum. Next, disconnect the belt from the drum and hooks. Loop the replacement belt back around the drum and through the motor’s hooks and pulley.

Find the most effective method for replacing defective parts.

If you have a faulty switch or a broken dryer belt, you should repair these defective parts as soon as possible. Depending on the broken item, you might be able to find a replacement piece in a store or online. Some features for your specific model number are only available from the manufacturer. Check with the Dryer vent cleaning Atlanta to see whether you need to order some parts from them. If you buy a part from a different store, you may discover that it isn’t appropriate with your gadget. It only operates with a piece obtained straight from the machine’s maker.

Examining the Drum Rollers

The drum rollers, which are at the back of the dryer, help it in turn. The drum rollers should be able to spin on their own. Untie the belt around the dryer drum and turn the machine on. Check to see if the drum rollers turn if the dryer won’t spin. HVAC Cleaning Atlanta says if your drum rollers broke down, you would need to replace them.

Reinstall the Drum Glides

The drum glides are around the dryer drum’s edge. If they break down, you will hear a plastic-on-metal grinding sound. If the glides allow it to wear out for an extended time, they may cause the dryer to stop spinning. Furthermore, you can remove the glide by popping it out of the plastic holes and then replacing it with new padding.

Observe the Pulley Assembly

The pulley component in your dryer maintains tension on the driving belt. It allows it to hold the drum and not slip off. But, the belt may not be able to stay on the drum if the pulley assembly is loose or damaged.

A pulley in a dryer is often made of small rubber or plastic wheels on a metal arm. A problem could be cracks in the wheel or arm of the pulley. Also, a stuck or difficult-to-move wheel may prevent the belt from spinning the drum.

Moreover, to gain access to the pulley assembly, do the following:

- Remove the top and front panel of the dryer and look for the idler pulley near the motor. The tension created by the driving belt is a significant factor in keeping the idler pulley in place.

- You should be able to pull the pulley out by slipping the belt away from the motor.

Thread the drive belt through the new idler pulley and motor. According to top professionals, you can replace the pulley with a new pulley assembly.