Duct hose is a necessary component of an hvac system. In this article, we will explain duct hose and its types.

What is a Duct Hose:

A ducting hose is a tube-like piece of equipment having an aperture at either end that transports anything from point A to point B. However, this is an overly broad and basic word that does not adequately describe the characteristics and operation of Rubber-ducting Cal’s hoses. We design duct hoses to transport a variety of materials. This range is divided into five categories: temperature-varying air, dust and other tiny particles, abrasives, bigger non-abrasive materials, and fumes.

A ducting hose is a tube-like piece of equipment with an opening at each end to convey something from A to B. However, it is an extremely broad and simplistic term that does not effectively define the properties and functioning of Rubber-ducting Cal’s hoses. The primary purpose of Our duct hoses is to convey a wide range of materials. Temperature-varying air, dust and other microscopic particles, abrasives, larger non-abrasive materials, and odors are all part of this spectrum.

Ducting is a broad topic with many distinct varieties for various uses. Our specialty is dust and fume extraction and ventilation, although we can also use other types of ducting for cables and other purposes that we do not offer.

Whenever we use a ducting hose, we need to clean it now and then. You can clean it at home. You can also contact any professional cleaner from HVAC cleaning Gainesville, GA.

Types of Duct Hose:

The two basic types of ducting are flexible and stiff. We can further subdivide these ducts as follows:

Flexible ducts:

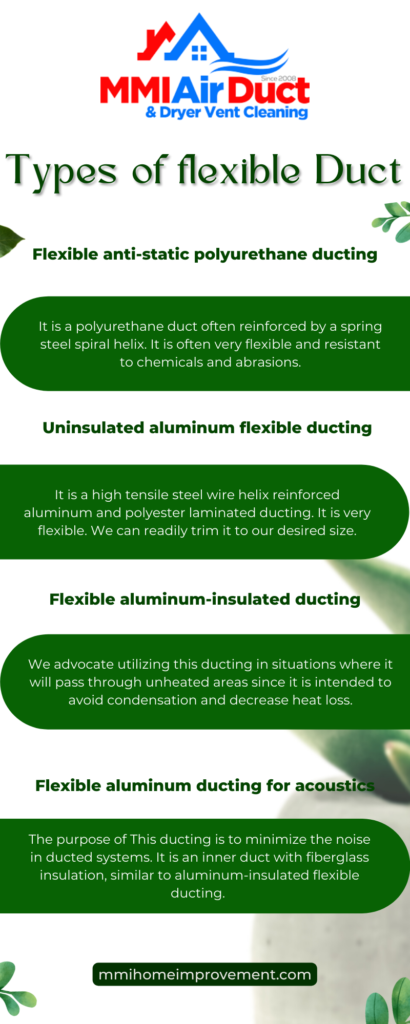

1. Flexible anti-static polyurethane ducting

It is a polyurethane duct often reinforced by a spring steel spiral helix. It is often very flexible and resistant to chemicals and abrasions. Typically, we use Anti-static PU flex for gasses, abrasive dust, powder & fiber extraction. We also use it for oil & spray mist extraction, and any application where electrostatic charge buildup is dangerous. Anti-static flexible polyurethane ducting is often available in a clear hue.

2. Uninsulated aluminum flexible ducting

It is a high tensile steel wire helix reinforced aluminum and polyester laminated ducting. It is very flexible. We can readily trim it to our desired size.

3. Flexible aluminum-insulated ducting

We advocate utilizing this ducting in situations where it will pass through unheated areas since it is intended to avoid condensation and decrease heat loss. This insulated ducting comprises an inner duct with fiberglass insulation that is covered by an outer jacket that functions as a vapor barrier.

4. Flexible aluminum ducting for acoustics:

The purpose of This ducting is to minimize the noise in ducted systems. It is an inner duct with fiberglass insulation, similar to aluminum-insulated flexible ducting. The inner core of acoustic aluminum flexible ducting, on the other hand, is perforated to allow for sound attenuation. It serves as thermal insulation and a vapor barrier in addition to acoustic insulation.

5. Multi-flex ducting

Because it is a mix of aluminum polyester and PVC, it is particularly helpful. When the duct is fully stretched, the inside of the ducting has a smooth surface, resulting in low-pressure dips and no dust gathering. Its hybrid nature offers increased strength, longevity, and stability, but its flexibility makes it simple to install and does not require any special cutting equipment.

6. Flexible ducting for car exhaust extraction

This sort of ducting is useful for removing exhaust gasses. Its elasticity allows it to be rollover-proof and withstand wear during the extraction of petrol and diesel exhaust gasses. Car exhaust extraction flexible ducting is normally durable and flexible, lightweight, highly flexible, resistant to severe mechanical stresses, and temperature resistant.

Use the below code to Embed this infographic

7. Flexible ducting made of food-grade PU

Companies manufacture these ducts out of food-grade polyurethane, which is odorless and tasteless. The EU and the FDA in the United States mandate the Materials for certain settings. This material is also resistant to microbes and hydrolysis.

8. Flexible silicone hoses for high temperatures

This form of ducting is a flexible ducting hose. We mainly use ir for both hot and cold gasses. We can easily find it in granulate dryers, hot air dryers, cleanroom ventilation, and semiconductor fabrication applications. However, we need to cover it with a silicon-coated glass fabric that will allow it to endure temperatures as high as 260 degrees Celsius.

9. Flexible metal ducting:

This ducting has high tensile strength and is crush resistant. It is ideal for absorbing vibration, thermal expansion, noise reduction, ducting of smoke and fumes, and dry bulk handling. Its second major advantage is its heat tolerance, which allows it to work at temperatures as high as 500 degrees Celsius.

10. Flexible PU ducting

People use Flexible PU ducting in suction and to convey dust, chips, and abrasive materials. It’s made up of polyurethane with a galvanized steel spiral, giving it a lot of liability.

Flexible ducting for welding arms.

Semi- flexible ducts:

We use Semi-flexible ducting to make flexible connections between various ventilation system components. Because it does not contain PVC, it doesn’t emit any harmful gasses in the case of any fire. However, it can operate at temperatures as high as 250 degrees Celsius.

1. Flexible ducting for welding arms

We install flexible ducts in welding extraction arms. Although, the makers of those extraction systems frequently offer it to ensure that it complies with all essential health and safety regulations.

2. Wyrm Flexible ducting

This type of duct is a very strong and long-lasting hose that is also very flexible and ozone resistant. Moreover, it is constructed of two spring steel helices and two double-reinforced layers of chloroprene-coated cotton.

Rigid Ducting:

Ducting made of sheet metal

This term broadly refers to any ducting made of sheet metal. However, people frequently use it in heating, ventilation, air conditioning, cooling, kitchens, dust, and fume extraction. Companies manufacture this Sheet metal ductwork under the UK standard DW144.

Spiral ducting

We use Galvanized steel to make spiral ducting (& occasionally aluminum). Spiral ducting is often less expensive than rectangular ductwork since it requires 32% less sheet metal.

Moreover, it is also less prone to leak when run in long, straight portions since it has fewer transverse and longitudinal joints.

Quick-Fit Ducting:

It is similar to ordinary spiral ducting, but companies engineered it to be easily assembled or removed if it changes or proves its premises. Because it has smoother inside surfaces, we install quick fit ducting after carrying a product through a system. Nordfab was the first to implement this technology.

Plastic Ducts:

1. Ducting made of round plastic

Plastic ducting is lightweight and simple to install. We frequently use this type of duct when there is a corrosion danger since it will not rust over time. There are Rectangular and circular plastic ducting available. We install these ducts when there is less space.

2. Fiberglass-lined ducting

Sheet metal ducts that have been lined with fiberglass for sound insulation are known as fiberglass-lined ducts. Companies seal the fiberglass so that it cannot enter the airstream.

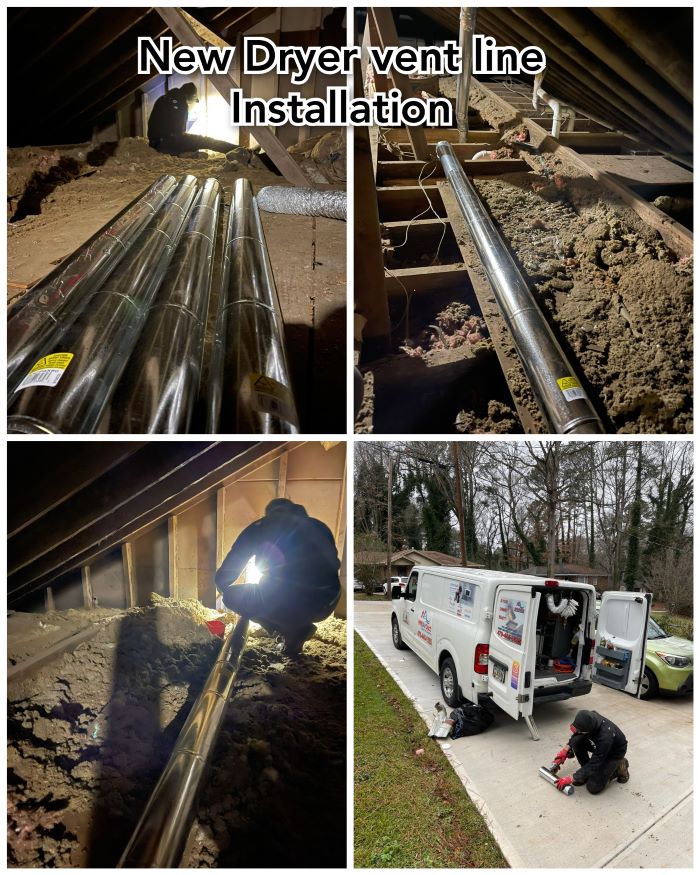

However, a technician can guide you about ducts more thoroughly. Dryer vent installation and repair Gainesville GA provides online consultation for it.

Conclusion:

In conclusion, we can say that duct hose is a quite broader term. You should always hire a consultant before installing any duct network.