Ductwork is one of the most critical parts of any home. It’s a haven for air conditioning, heat, and ventilation. Without proper Insulation, ductwork can lose a significant amount of energy, resulting in higher bills and wasted resources. This blog post will discuss the different types of Insulation for ductwork so you can choose the best one for your home.

However, we only utilize a few different insulations for HVAC ducts. Moreover, because we commonly install the ducts above the ceiling, people cannot see duct insulations. We’ll now list the four main categories of duct insulation and their descriptions.

The following are the four most popular duct insulation types:

- Insulation made of fiberglass and aluminum foil

- Cross-linked Polyethylene Insulation Foam

- Perforated metal sheet with Rockwool Insulation

- Insulation made of fiberglass and aluminum foil with holes

We typically install the Insulation on the exterior of ducts to stop moisture and energy loss. People occasionally use insulations on the internal surface of ducts to reduce noise, particularly those that serve air handling devices (AHUs). Some insulations are not suitable for internal duct applications. With that said, let’s get started.

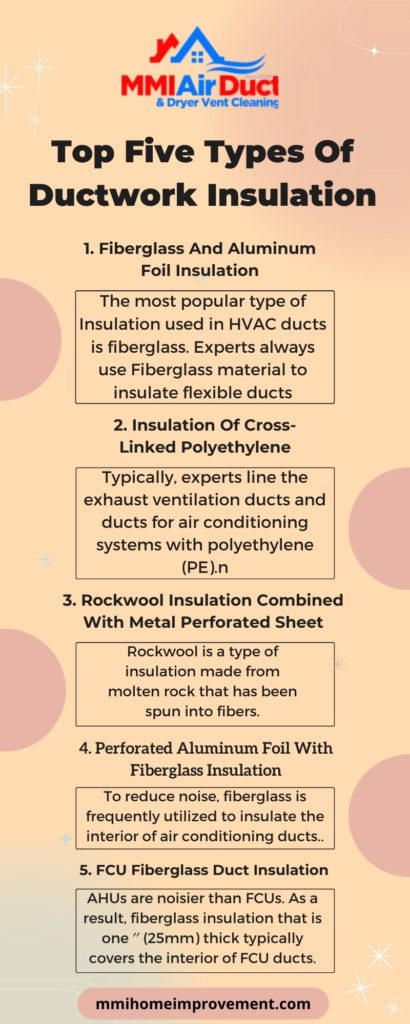

Top Five Types Of Ductwork Insulation

You could be wasting energy and money if you don’t insulate your ductwork. For example, the home loses up to 40% of its heating and cooling energy through poorly insulated ductwork. Insulating your ducts allows you to keep the cool air in during the summer and warm air in on the chilliest winter days.

Regarding your home’s comfort and energy efficiency, ductwork insulation is equally as crucial as other insulation materials. Ductwork insulation is the first line of defense against heat loss and energy waste. Here are four types of ductwork insulation you should know about. Learn more about the method to utilize duct insulation wrap.

1. Fiberglass And Aluminum Foil Insulation

The most popular type of Insulation used in HVAC ducts is fiberglass. Experts always use Fiberglass material to insulate flexible ducts. To keep the fiberglass material together, fiberglass insulations include an exterior layer of shiny aluminum foil.

Take note that the duct’s initial three pieces lack any exterior insulation. They were internally insulated to muffle the noise produced by the AHU, which is why.

Different insulation specifications apply for internal and outdoor duct uses. Duct joints must still have exterior Insulation to stop dampness.

For supply and return air ducts, technicians require fiberglass insulation of at least one ′′ (25mm) thickness. The fiberglass insulation’s density should be at least 2 lb/ft3 (32 kg/m3), and its thermal conductivity should not exceed 0.24 BTU.in/hr/sqft/°F (0.035 W/mK). Contact us if you are looking for commercial air duct and dryer vent cleaning Buford.

However, the temperature difference between the air moving inside the duct and the air surrounding the duct’s exterior determines how thick the Insulation should be. Typically, the room temperature is around 75°F (24°C), while the AHU supply air temperature is around 57°F (14°C). Therefore, the temperature difference may be about 20°F (10°C). If you keep the fiberglass at a density of 2 lb/ft3 (32 kg/m3), employing one ′′ (25mm) thick Insulation is acceptable.

2. Insulation Of Cross-Linked Polyethylene

Typically, experts line the exhaust ventilation ducts and ducts for air conditioning systems with polyethylene (PE). When the duct is visible, people tend to use PE insulations more regularly. . Due to the higher cost of PE insulations compared to fiberglass insulations, some people do not typically use the PE foam to insulate concealed ducts.

Because of the increased temperature difference, if the duct was linked to an air conditioner, the insulation thickness is typically 3/8′′ (9mm).

Because they don’t have creases like fiberglass insulated ducts, PE insulated ducts are more visually pleasing. In addition, working with PE insulations is safer than working with fiberglass insulations.

In some cases, hospital construction projects may require at least 3/4′′ (20mm) thick PE insulations, with the PE foam’s density being no less than 2 lb/ft3 (30 kg/m3). The fiberglass’s thermal conductivity being no greater than 0.24 BTU .in/hr/sqft/°F (0.035 W/mK).

However, based on my experience, PE insulations with thicknesses of 3/8′′ (9mm) and 1/2′′ (12mm) are more typical for residential and commercial buildings. Hospitals typically have higher standards than other buildings because they need low supply air temperature.

Also Read: How To Replace A Dryer Vent On Roof

3. Rockwool Insulation Combined With Metal Perforated Sheet

Oversized air conditioning ducts frequently have Rockwool or stone wool on the interior surface to reduce noise. Internal insulations of AHUs and FCUs typically extend about 20 feet (6 meters) and 4 feet (1.2 meters) from the supply air outlet.

Below is a photo of an AHU duct’s interior. Rockwool is used as Insulation, and perforated metal sheets keep the Rockwool in place.

Sometimes Rockwool can be replaced with fiberglass that meets the exact specifications. However, Rockwool is more desirable since it resists tearing even in strong winds seen in AHU ducts.

The interior Insulation of air conditioning ducts must typically be at least 2 inches (50 millimeters) thick and made of Rockwool Insulation. Rockwool should have a density of no less than 2 lb/ft3 (32 kg/m3) and thermal conductivity of no more than 0.24 btu. in/hr/sqft/°F (0.035 W/mK).

To strengthen the integrity, perforated metal plates rather than perforated metal sheets should be utilized when the air velocity is more than 1500 fpm (7.6 m/s). The perforated metal plate is approximately 24G thick (0.6mm).

4. Perforated Aluminum Foil With Fiberglass Insulation

To reduce noise, fiberglass is frequently utilized to insulate the interior of air conditioning ducts. For internal Insulation of FCU ducts, fiberglass with perforated aluminum foil is typically employed. High wind speeds in AHU ducts have the potential to rip aluminum foil and fiberglass.

5. FCU Fiberglass Duct Insulation

AHUs are noisier than FCUs. As a result, fiberglass insulation that is one ′′ (25mm) thick typically covers the interior of FCU ducts. Fiberglass should have a density of at least 2 lb/ft3 (32 kg/m3) and thermal conductivity of no more than 0.24 btu. in/hr/sqft/°F (0.035 W/mK). Perforated foils are required for sound insulation applications rather than solid foils because the material requires the perforations to absorb sound efficiently. To avoid the fiberglass breaking off and posing health risks, it is crucial to avoid utilizing too large of a hole.

There are additional forms of duct insulation in addition to the four mentioned above, including polyurethane, closed-cell (superlon), and pre-fabricated ducts. However, when working with air conditioning ducts, you will most likely come across these four types of duct insulation.

Must Read: How To Install Ceiling Register Covers